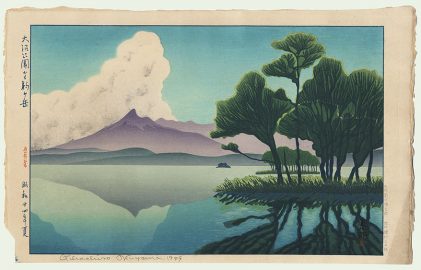

Woodcut print based on a painting by Ogata Korin (1658 – 1716).

Author: Chris Wells

BANSKIA SCRUB 2

Back in January Sam and I collected seed from the Banskia Scrub, and now we have a small forest of seedlings.

The Wirilda seedlings (Acacia retinoides) grew quickly; we planted them in the Paddock a few weeks ago.

Here in the photo, on the left, is a pot of the Southern Cypress Pine, Callitris preissi; in the middle, Drooping Sheoak, Allocasuarina verticillata; on the right, a miscellany including sheoak, and Moonah, Melaleuca lanceolata.

The grass trees, Xanthorrhoea, have not emerged – yet.

Muntries, Kunzea pomifera, failed – but I can propagate it from cuttings, with a bit of luck.

INSIDE THE BOATSHED

I have been preparing cypress beadings at a portable bench inside the boatshed.

Apart from the entrance, which still needs double doors, our work area is enclosed, and is proving to be a comfortable and – dare I say it – enchanting space.

Outside, the sun comes and goes, and a chilly wind blows from the south; inside, the light is steady, and the cypress walls provide warmth and protection. It is a light-filled environment, which will be lighter still once we have skylights in place (above the two permanent benches), and the four LED light-bulbs installed at stategic points.

At first, I was worried about shedding cypress wood-shavings onto a pristine and very beautiful cypress floor…but after all, it is a workshop, not a luxury apartment – and in due course I got used to standing in the sea of shavings and wood-dust (which I later swept up).

The electrican, who is an enthusiast and boatshed devotee, will be here in the next week or so. I understand the LED lights will last for thirty two years. At that stage, I expect we will have to replace them with (no doubt) superior technology.

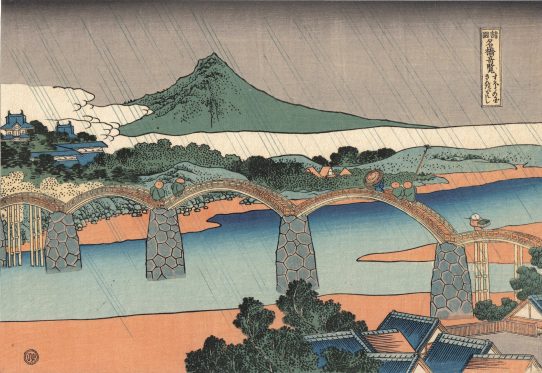

HOKUSAI 2

HALF A WALL

The floor was swept and clean; the pins were all swept up and stuck into pin papers; the ends of thread and little silk snippets were all tidied away, and gone from the floor.

But upon the table! Oh joy – the tailor gave a shout!

There – where he had left plain cuttings of cloth – there lay the most beautifullest coat and gold-brocaded waistcoat that ever were worn by a mayor of Gloucester.

There was embroidery upon the cuffs and upon the pocket flaps and upon the skirts of the coat: it was cherry-coloured corded silk, lined with yellow padusoy; there were one-and-twenty buttons.

The waistcoat was of peach-coloured satin, worked with thread of gold and silver.

Everything was quite finished except just one single cherry-coloured button-hole; and where that buttonhole was wanting, there was pinned a little scrap of paper, with these words – in teeny weeny writing –

“no more twist”.

From: The Tailor of Gloucester

by Beatrix Potter

First published by Frederick Warne & Co. Ltd

London 1903

The search is on for twenty-six rough-sawn Native Cypress weatherboards, with rebates.

HOKUSAI 1

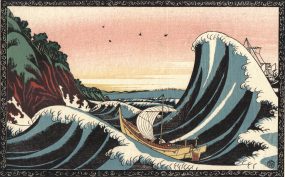

THE MYSTICAL BOAT

INSTALLING THE GLASS 3

The western wall is finally sealed.

Sam and I installed the heavy pane of glass yesterday. It is meant to be storm-proof.

You can see the space we cleared on the southern and western side of the floor, in readiness for two work-benches. Jonny has been looking after the benches, on my behalf – the older of the two, for about twenty years. Now that is true brotherly forebearance, and generosity.

I’m glad to report that the wooden floor (as far as we could see) is in excellent condition. There are no termites.

EASTERN WEATHERBOARDS 3

That big jump across the entrance was something of a challenge. I wanted the boards to line up from one edge of the boatshed to the other. There is a bit of variation – perhaps three millimetres – which as far as I am concerned is entirely acceptable.

At any rate, I am not inclined to dismantle the wall and try again.

I think the entrance looks like a welcoming one, defined by the lovely colours of native cypress.